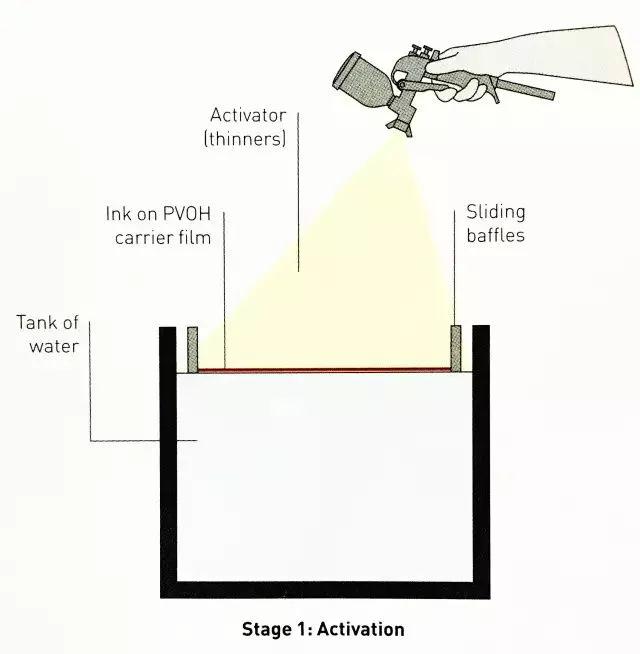

Water transfer printing technology is a printing method that uses water pressure to hydrolyze polymer on transfer paper/plastic film with colored patterns.

As people’s requirements for product packaging and decoration increase, the use of water transfer printing is becoming more and more widespread. The principle of indirect printing and perfect printing effect have solved many problems in surface decoration of products.

Various ceramics, glass, and paper flowers are all produced using water transfer printing technology.

Process:

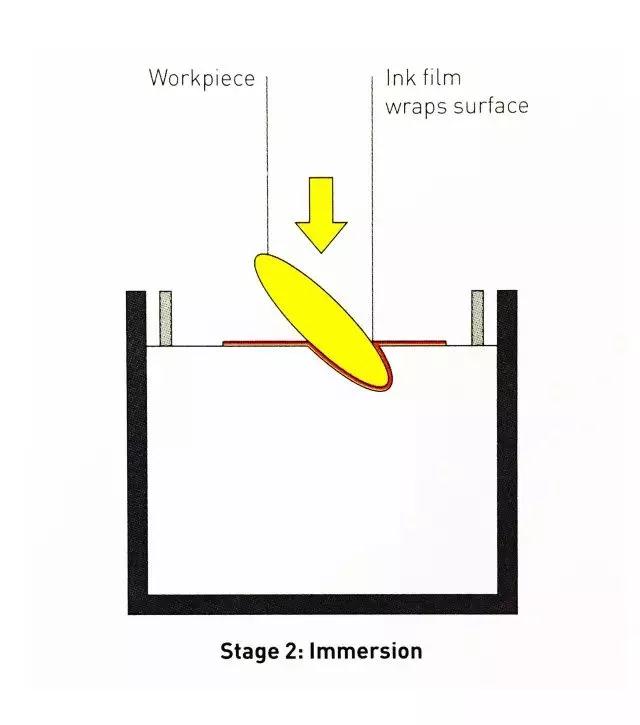

Making transfer paper → Soaking the paper with flower patterns → Transferring the patterns onto the surface → Drying → Finished product.

The water transfer printing technology is a complete transfer printing process that covers the entire surface of the product.

The difference between water transfer paper and water transfer film:

1. Water transfer paper has a backing paper, while water transfer film does not. 2. Water transfer paper can be printed using a printer, while water transfer film is printed using a gravure printing machine. 3. Water transfer paper does not require plate making, making it suitable for small batch customization, while water transfer film requires plate making which is charged per color, and is used for large-scale industrial printing. 4. Water transfer paper is suitable for less complex shapes, while transfer film has no restrictions on shape.